In the dynamic world of construction, staying ahead means embracing innovations that boost efficiency, durability, and overall project success. Enter rebar bar couplers and cold-forging machines – two transformative technologies shaping the future of construction methods.

Rebar Bar Couplers: Streamlining Strength

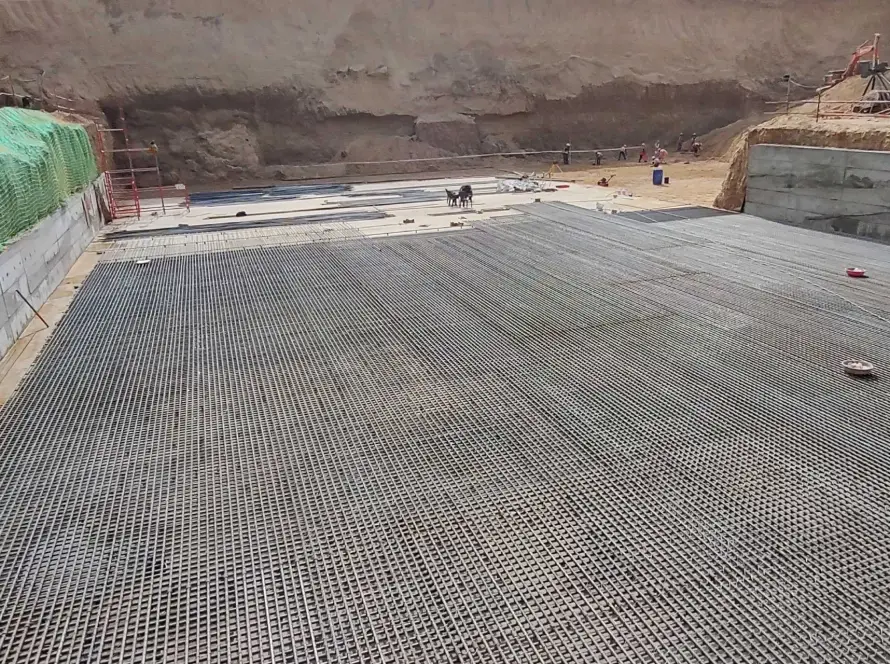

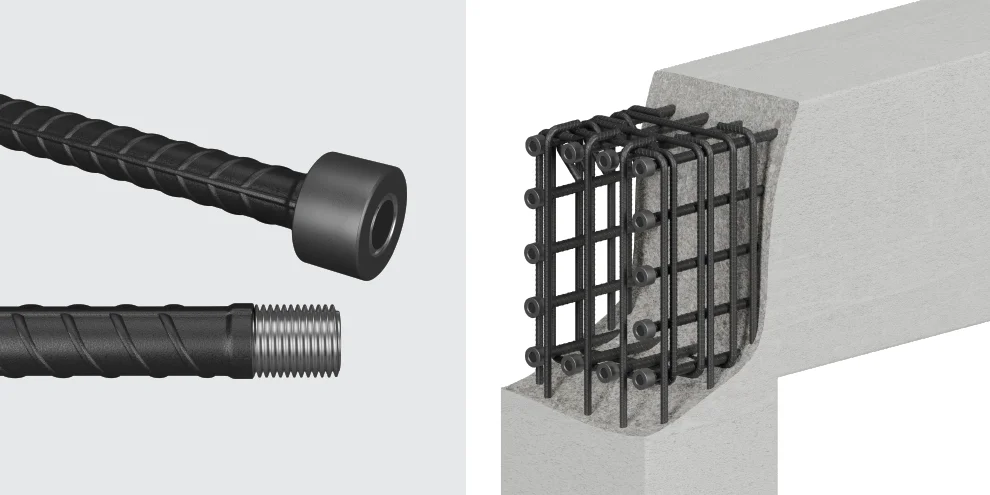

Traditional methods of reinforcing concrete structures involved time-consuming manual tying of rebars. Rebar bar couplers have changed the game by offering a mechanical solution that connects reinforcing bars seamlessly, eliminating manual labor challenges.

Advantages of Rebar Couplers:

Time Efficiency for Construction Projects: Rebar bar couplers significantly reduce construction time, providing a quicker project turnaround without compromising structural integrity.

Cost Savings in Construction: Reduced labor requirements lead to cost savings, making rebar bar couplers a cost-effective solution with long-term benefits.

Enhanced Structural Integrity: Mechanical connections ensure a robust bond between reinforcing bars, reducing the risk of structural failure.

Versatility in Construction: These couplers accommodate various rebar sizes and types, offering flexibility in construction projects and simplifying planning and execution.

Cold-Forging Machines: Shaping Success

Cold forging, a metalworking process without the use of heat, is pivotal in shaping metal components, including rebar couplers. Cold-forging machines have become essential in producing high-quality, precision-engineered components.

Advantages of Cold-Forging Machines:

Increased Material Strength for Construction Components: Cold forging imparts greater strength to metal components, ensuring durability and enhanced load-bearing capacities in construction applications.

Precision and Consistency in Metal Component Production: Cold forging allows for precise and consistent components with tight tolerances, vital for the proper functioning of construction elements.

Material Savings and Sustainability: Minimal material waste in the cold-forging process contributes to sustainable construction practices, aligning with cost-effectiveness and environmental consciousness.

High Production Rates for Construction Efficiency: Cold-forging machines operate at high speeds, facilitating large-scale production of components to meet the demands of fast-paced construction projects.

Conclusion:

Rebar bar couplers and cold-forging machines are at the forefront of innovation in the construction industry. By embracing these advancements, construction professionals can achieve greater efficiency, cost-effectiveness, and structural integrity in their building projects. As the construction sector continues to evolve, incorporating rebar bar couplers and cold-forging machines isn’t just an upgrade; it’s a strategic move toward the future of construction.