Introduction

Rebar bar couplers may not be the first thing that comes to mind when considering construction projects, but they play a vital role in ensuring the structural integrity of various concrete structures. In this article, we will explore the ten reasons why rebar bar couplers are essential in construction projects. From enhancing stability to promoting sustainability, these innovative connectors offer numerous benefits that shouldn’t be overlooked.

What Technical Superior say’s :

Rebar Couplers, which are manufactured by the leading Rebar Coupler Supplier in India, Magnatech, function as continuous reinforcement and gain strength mechanically, unaffected by concrete. This imparts ductility to RCC structures that is not dependent on concrete. The verified cyclic performance of rebar ensures its structural integrity in the face of natural, man-made, and seismic events. Rebar’s continuity provides an excellent grounding provision for electrical current.

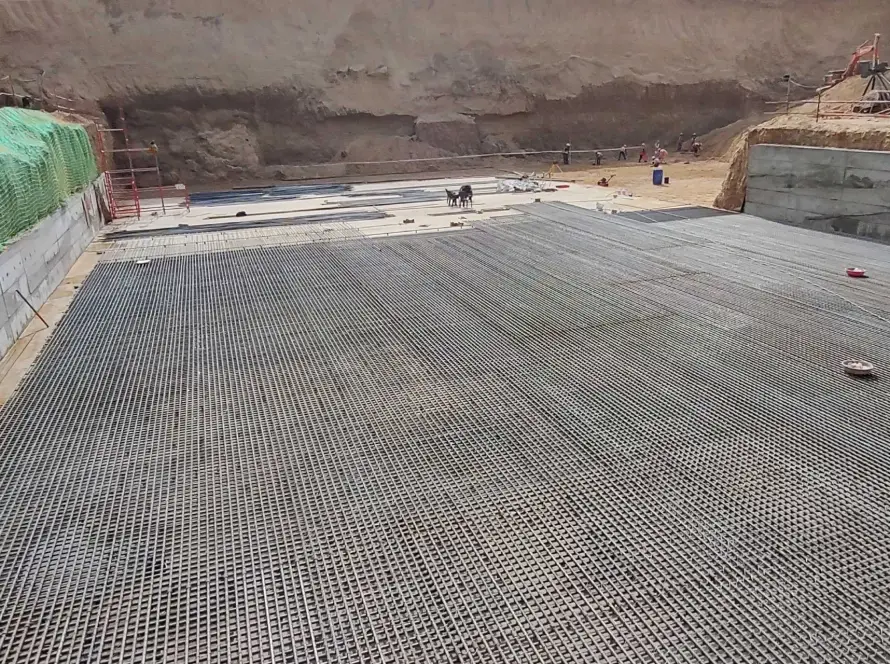

1. Enhanced Structural Stability

Rebar bar couplers provide enhanced structural stability by securely connecting two reinforcing bars. Without these couplers, construction projects heavily rely on overlapping or welding the bars, which can lead to weaker joints and potential failure points in the future. By utilizing rebar bar couplers, construction professionals can ensure a more robust and stable structure, capable of withstanding heavy loads, seismic activities, and other external forces.

2. Time and Labor Efficiency

One of the primary advantages of rebar bar couplers is their ability to significantly reduce construction time and labor requirements. Traditional methods, such as overlapping or welding bars, often involve time-consuming and labor-intensive processes. However, with bar couplers, the installation process becomes much more efficient. These couplers eliminate the need for complex procedures, allowing for faster construction, reduced labor costs, and improved project timelines.

3. Cost Savings

In addition to time and labor efficiency, rebar bar couplers offer substantial cost savings for construction projects. Since the installation process is streamlined and requires fewer resources, there is a reduction in material wastage and associated expenses. Moreover, the reduced labor requirements contribute to additional cost savings, making bar couplers a preferred choice for both small- and large-scale construction initiatives.

4. Flexibility in Design

The inherent flexibility of rebar bar couplers allows for increased design freedom in construction projects. Unlike traditional methods that limit the positioning and arrangement of reinforcing bars, bar couplers enable architects and engineers to create structures with more intricate designs, complex geometries, and diverse load-bearing requirements. This flexibility not only enhances the aesthetic appeal of the structure but also optimizes its overall structural performance.

5. Durability and Longevity

Rebar bar couplers are engineered to ensure the long-term durability and longevity of concrete structures. By eliminating the need for potential weak points such as overlapping or welded joints, bar couplers enhance the structural integrity and resistance to corrosion. This, in turn, significantly extends the lifespan of the structure and reduces maintenance and repair costs over time. With the use of bar couplers, construction projects can withstand the test of time and environmental challenges more effectively.

6. Ease of Inspection

Construction projects require meticulous inspection to ensure compliance with safety and quality standards. Rebar bar couplers offer an advantage in this regard by providing easier access for inspection. Unlike welded joints, which may require X-ray or ultrasonic testing for a thorough examination, bar couplers allow for visual inspection, making it easier to identify potential issues or deficiencies during the construction process. This simplifies the inspection process and facilitates timely corrections, ensuring superior construction quality.

7. Sustainable Construction Practices

Sustainability is a growing concern in the construction industry, and rebar bar couplers contribute to sustainable construction practices. By minimizing material wastage and reducing the carbon footprint associated with welding or overlapping, bar couplers promote environmentally friendly construction processes. Additionally, their durability and longevity minimize the need for frequent replacements, reducing overall material consumption and waste generation. Choosing bar couplers reflects a commitment to sustainable construction practices and environmental stewardship.

8. Adaptability to Various Construction Projects

Rebar bar couplers are highly adaptable and can be utilized in a wide range of construction projects. Whether it’s a high-rise building, a bridge, an airport runway, or a foundation, bar couplers can accommodate diverse construction requirements. Their versatility ensures that the benefits of enhanced structural stability, time efficiency, cost savings, and sustainability can be realized across different applications, making them an essential component in modern construction practices.

9. Compliance with Quality Standards

Bar couplers are designed to meet and even exceed stringent quality standards established by regulatory bodies and construction codes. Manufacturers subject their products to rigorous testing and inspection to ensure they comply with the necessary requirements. By using these certified and quality-tested couplers, construction professionals can have confidence in the structural integrity and performance of their projects, while also satisfying regulatory obligations.

10. Industry Recognition and Adoption

Rebar bar couplers have gained substantial recognition and widespread adoption within the construction industry. As more professionals realize the benefits and advantages offered by bar couplers, their usage becomes increasingly prevalent. This industry-wide recognition reflects the proven effectiveness and reliability of bar couplers, further underscoring their essentiality in construction projects.

Conclusion

In conclusion, Magnatech rebar bar couplers are an indispensable element in the realm of construction. They offer enhanced structural stability, time and labor efficiency, cost savings, design flexibility, durability, ease of inspection, sustainable construction practices, adaptability, compliance with quality standards, and industry recognition. From skyscrapers to intricate architectural wonders, the importance of rebar bar couplers cannot be overstated. Incorporating these connectors into construction projects ensures not only the safety and longevity of structures but also drives innovation and efficiency in the ever-evolving construction industry.